PRODUCTS

APV LAB HOMOGENIZERS

Homogenizers – Theory of Operation

The homogenization process is used to enhance product characteristics, add value and/or lower costs. It is a physical process that mixes immiscible liquids into an emulsion. The homogenizer is basically a positive displacement pump to which a homogenizing valve is attached. The fluids entering the homogenizer are forced through a small gap at high pressure. This causes a rapid increase in velocity and decrease in pressure creating turbulence and pressure differences that cause disruption and dispersion of the particles.

MIXERS

Mixing and Blending is one of SPX FLOW’s core technologies, designed to help customers develop new products and processes, improve product quality and shelf-life and provide better consistency. An extensive mixer portfolio offers the flexibility to handle all types of products, quickly and efficiently. Our specialist mixing and blending systems fulfill customer requirements in industries as diverse as processed food, beverage & brewing, dairy and personal care.

With food safety of paramount importance, all APV products are designed to the highest hygiene standards for easy cleanability. And they are supported by pro-active service agreements, where latest technologies, such as crack testing, are used to identify and rectify possible faults, well before they develop into a real problem.

APV Plate Heat Exchangers

Gasketed Plate Heat Exchangers – Sanitary

Sanitary applications represents a unique set of requirements to solve the job and live up to the strong demands for cleanability, accessability and product integrity. APV’s sanitary portfolio is known for its high quality and value adding features. With a wide range of frame compression technologies, connection types and sanitary accessories for increased cleanability, APV can cover all heat transfer needs in the sanitary market place.

Gasketed Plate Heat Exchangers – Industrial

The global applications for industrial heat exchangers calls for a wide and deep product range, putting great demand on the equipment. SPX FLOW’s portfolio of APV ParaFlow is designed to match your needs, whether this is for very small flows, or the extra-large kind, up to 4,500 m3/h. With our selection of materials, connections and accessories, we can supply equipment for practically every heat transfer need. The ParaWeld and Paramine technologies expand the boundaries for gasketed plate heat exchangers. Added our long experience in after sales services, SPX FLOW is your all-round partner for heat transfer.

APV PUMPS

W+ Series Centrifugal Pumps (IEC)

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind.

C-Series Centrifugal Pumps

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind.

Rotary Lobe Pumps – DW Pumps

The DW series is SPX FLOW’s latest technology rotary lobe pump range. No other rotary lobe pump on the market today offers such a wide range of features in one pump. The 26 DW models are hygienic, 3-A and EHEDG approved and cover all requirements from 3 litres /100 revs to 1016/100 revs. Maximum pressure up to 30bar. All product contact parts are AISI 316L stainless steel and elastomers comply with FDA-requirements.

Rotary Lobe Pumps – HL Series

Product Benefiits

- Pumps with flushed double mechanical seals can run dry indefinitely

- Very low shear, product not damaged during pumping

- No internal rotor contact

- Large fluid cavities can pump liquids with large solids

- No cross-contamination of lubricating oil into product zone due to unique gear case design

- Pumps are energy efficient and easily cleaned, maintained and repaired

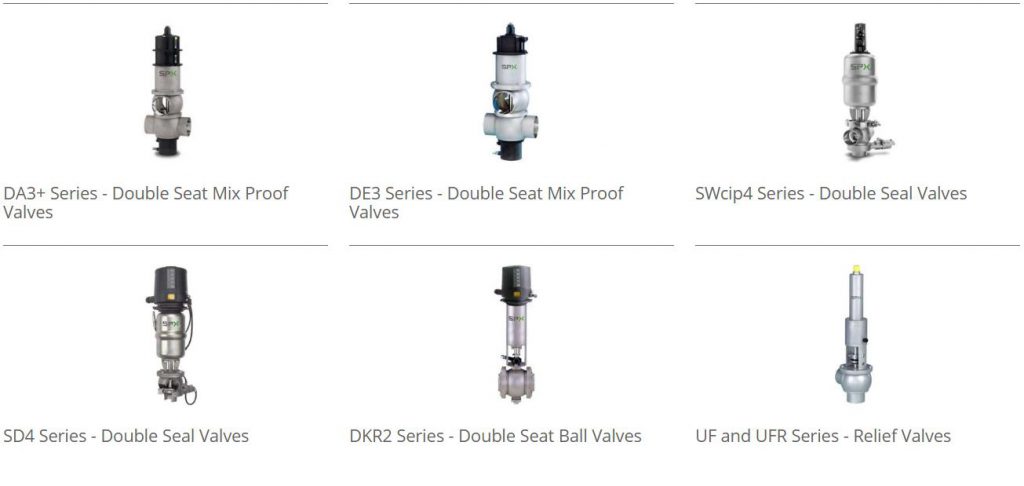

VALVES

SPX FLOW is a leading innovator of solutions with decades of experience in valve design. Years of intensive product development on a worldwide scale, has enabled SPX FLOW to offer a complete range of hygienic valves in the brewery, dairy, food, beverage, chemical, health care and pharmaceutical industries.