The homogenization process is used to enhance product characteristics, add value and/or lower costs. It is a physical process that mixes immiscible liquids into an emulsion. The homogenizer is basically a positive displacement pump to which a homogenizing valve is attached. The fluids entering the homogenizer are forced through a small gap at high pressure. This causes a rapid increase in velocity and decrease in pressure creating turbulence and pressure differences that cause disruption and dispersion of the particles.

Mixing and Blending is one of SPX FLOW’s core technologies, designed to help customers develop new products and processes, improve product quality and shelf-life and provide better consistency. An extensive mixer portfolio offers the flexibility to handle all types of products, quickly and efficiently. Our specialist mixing and blending systems fulfill customer requirements in industries as diverse as processed food, beverage & brewing, dairy and personal care.

Sanitary applications represents a unique set of requirements to solve the job and live up to the strong demands for cleanability, accessability and product integrity. APV’s sanitary portfolio is known for its high quality and value adding features. With a wide range of frame compression technologies, connection types and sanitary accessories for increased cleanability, APV can cover all heat transfer needs in the sanitary market place.

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind.

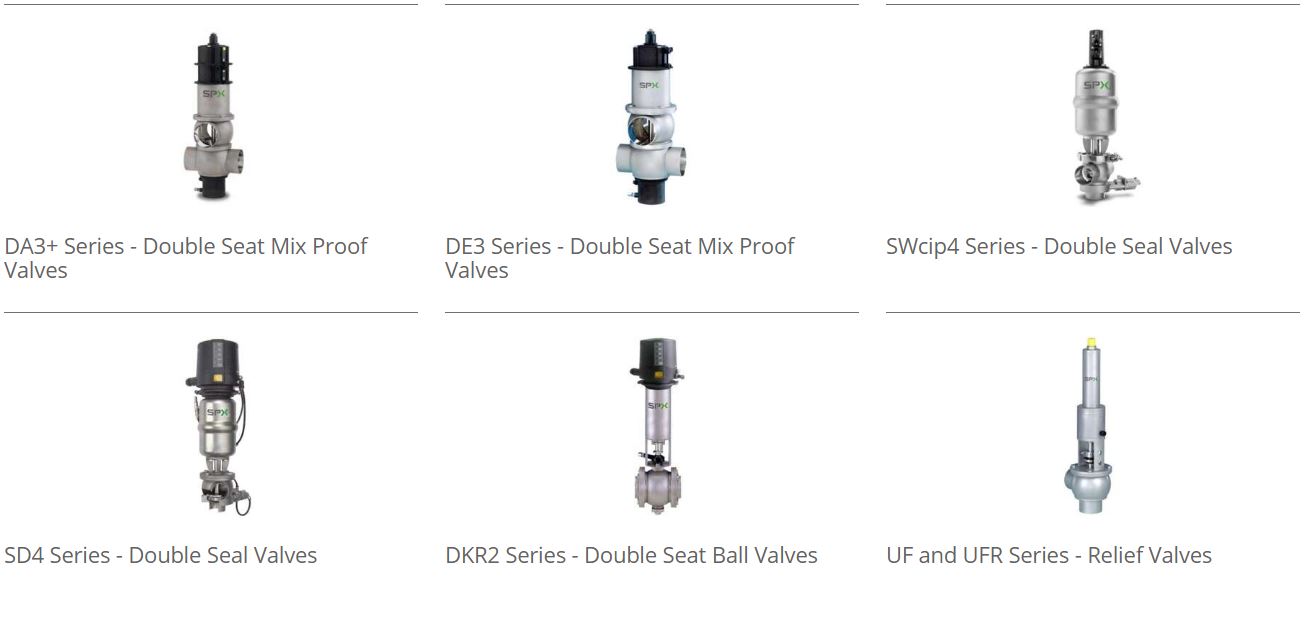

SPX FLOW is a leading innovator of solutions with decades of experience in valve design. Years of intensive product development on a worldwide scale, has enabled SPX FLOW to offer a complete range of hygienic valves in the brewery, dairy, food, beverage, chemical, health care and pharmaceutical industries.

Proper operation and maintenance are key to reliable operation and maximum lifetime performance of your equipment. Several issues can affect equipment performance: Changes in flow rate, fouling, defective parts, and leakage are all factors that can impact your return on investment over a period before they become critical problems.

Please be invited to attend our Open House program to gain a tangible and in-depth understanding of our products, services, and operations, with a strong emphasis on our commitment to quality. This event will highlight our aftermarket support capabilities and service team through interactive presentations and live demonstrations.

The purpose of this Open House is to help you recognize the critical role of aftermarket capabilities before making your decision on equipment brands. We will focus on essential factors such as spare parts inventory, service team efficiency, and what you should expect from a supplier to ensure long-term reliability and continuous support for your equipment.

NFLOW is an official distributor of SPX FLOW in Thailand.

Need a price quotation?

Enquire now